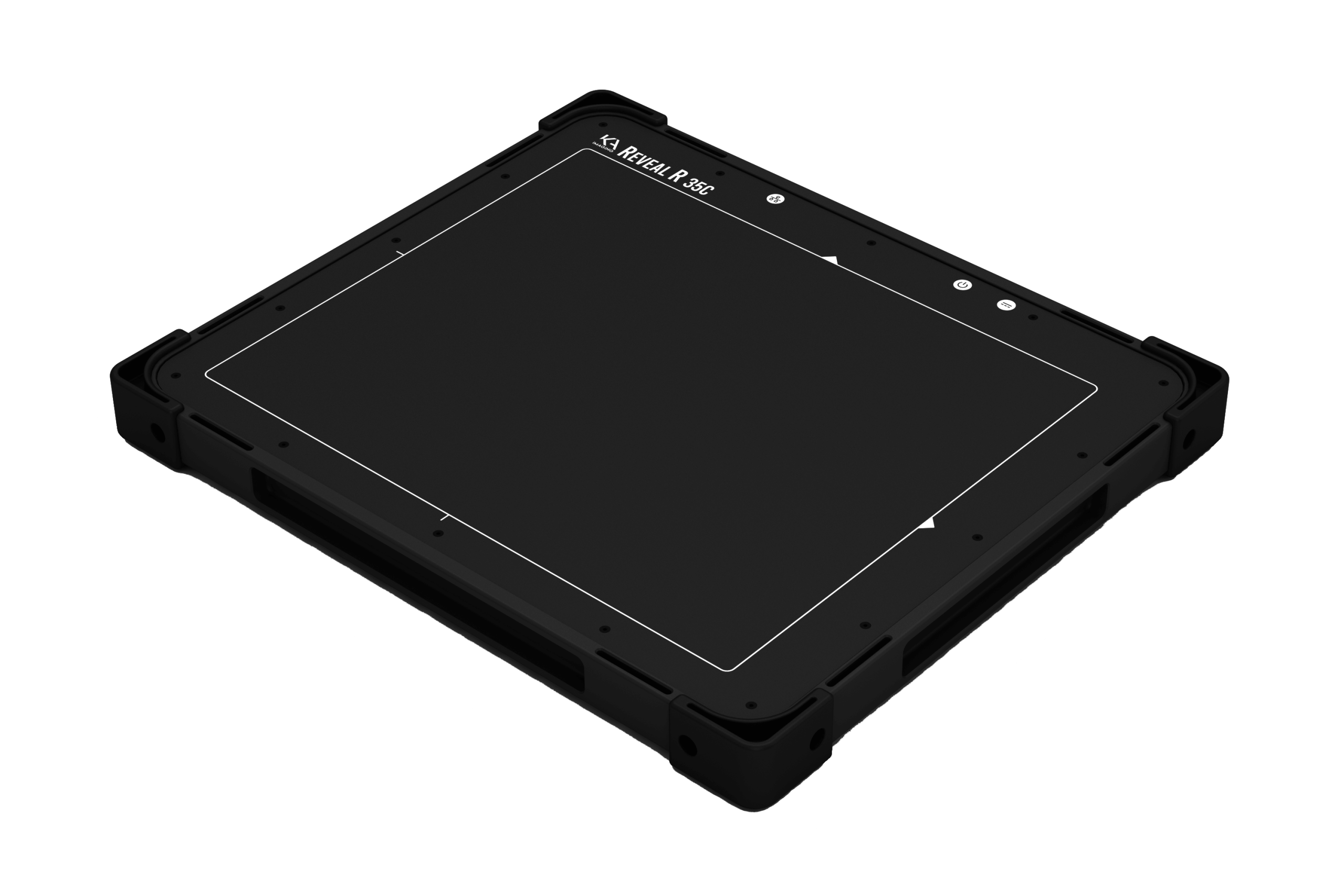

Reveal™ R 35C

Our rugged portable triple-energy X-ray detector, powered by SpectralDR® technology.

Traditional X-ray inspection is currently inefficient due to challenges like poor spatial resolution and contrast. This results in missed defects, lower yield, and higher costs—a significant problem for any manufacturer. Meet Reveal™ R 35C, our rugged triple-energy X-ray detector, a solution to take your X-ray images to the next level.

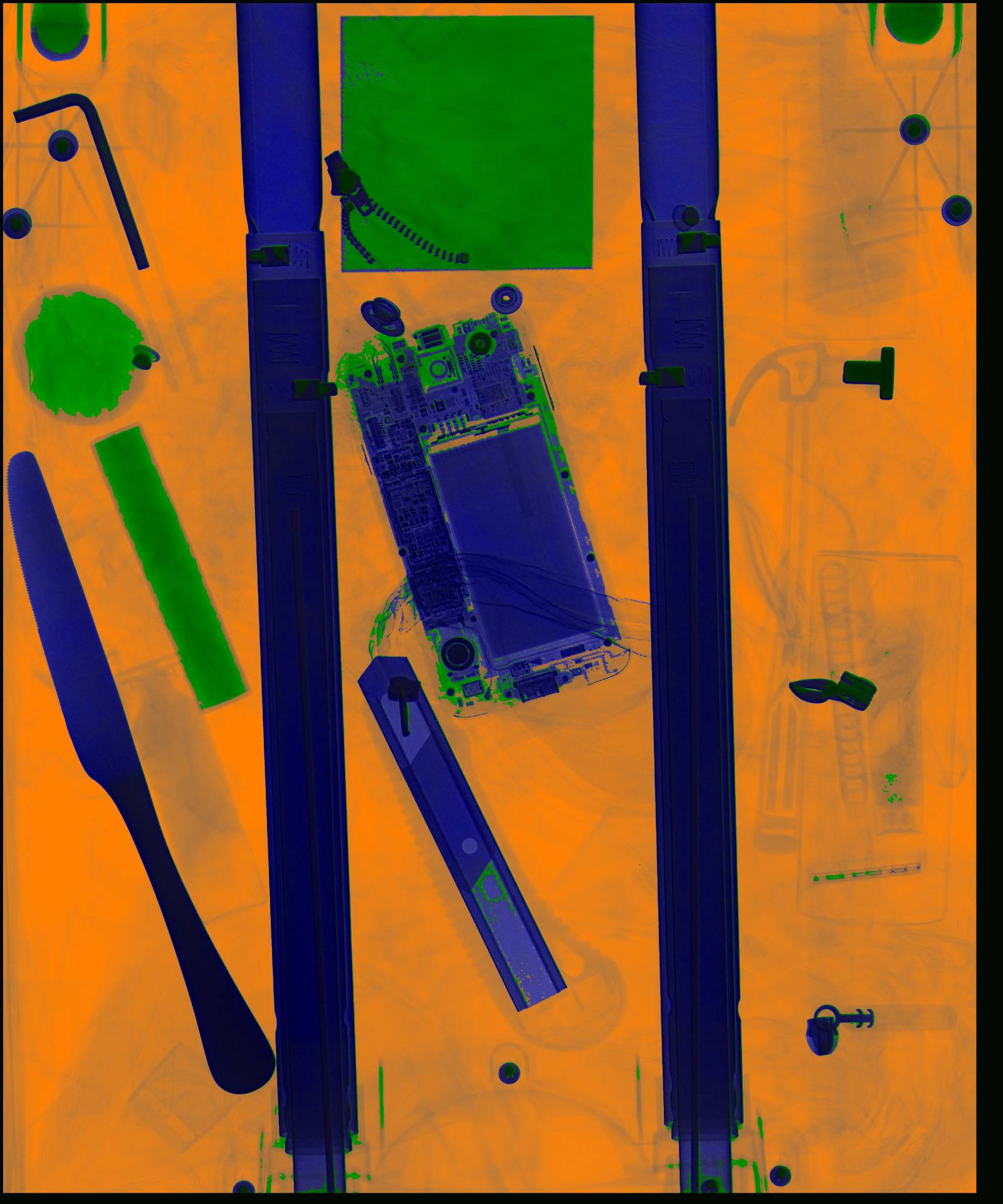

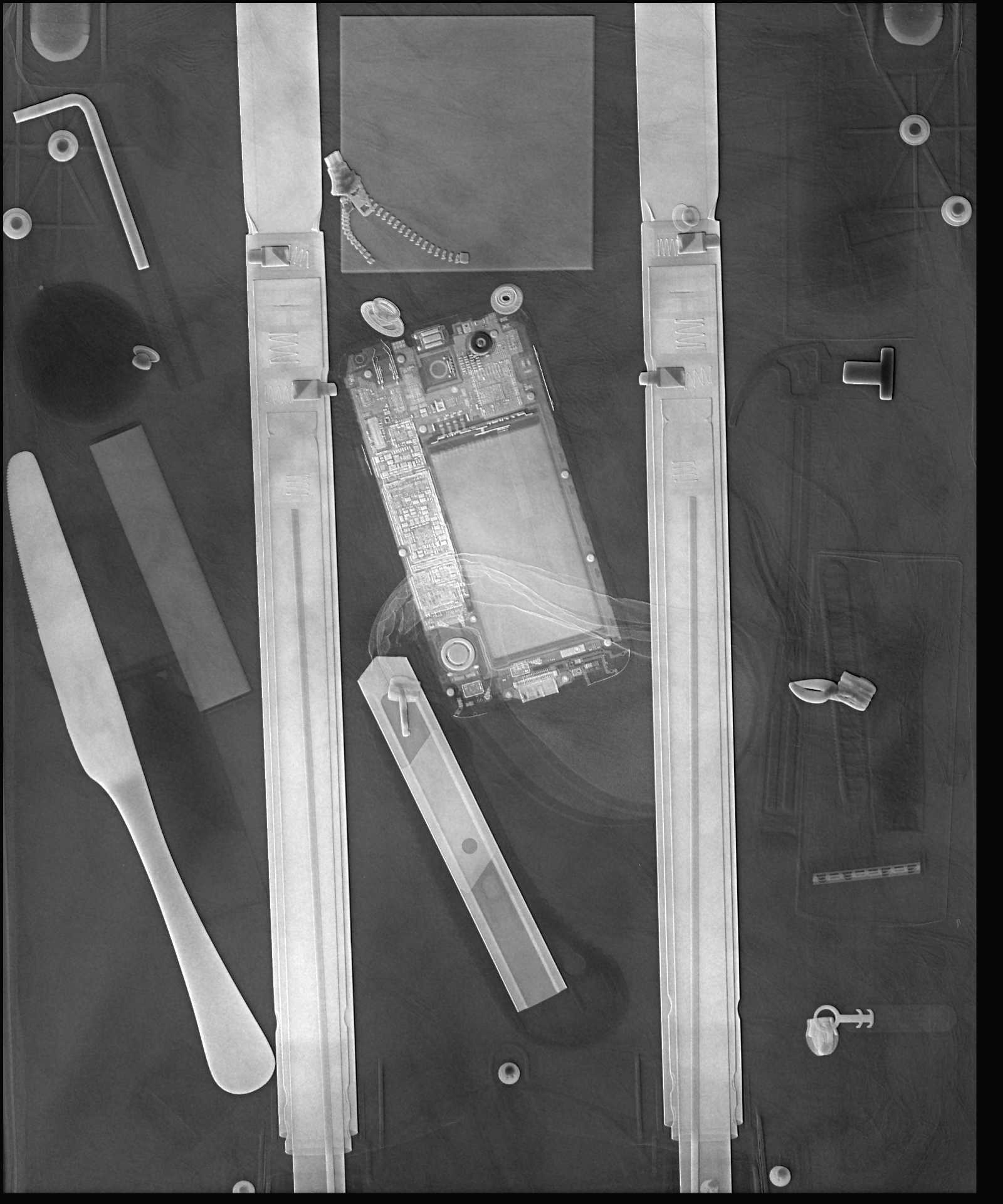

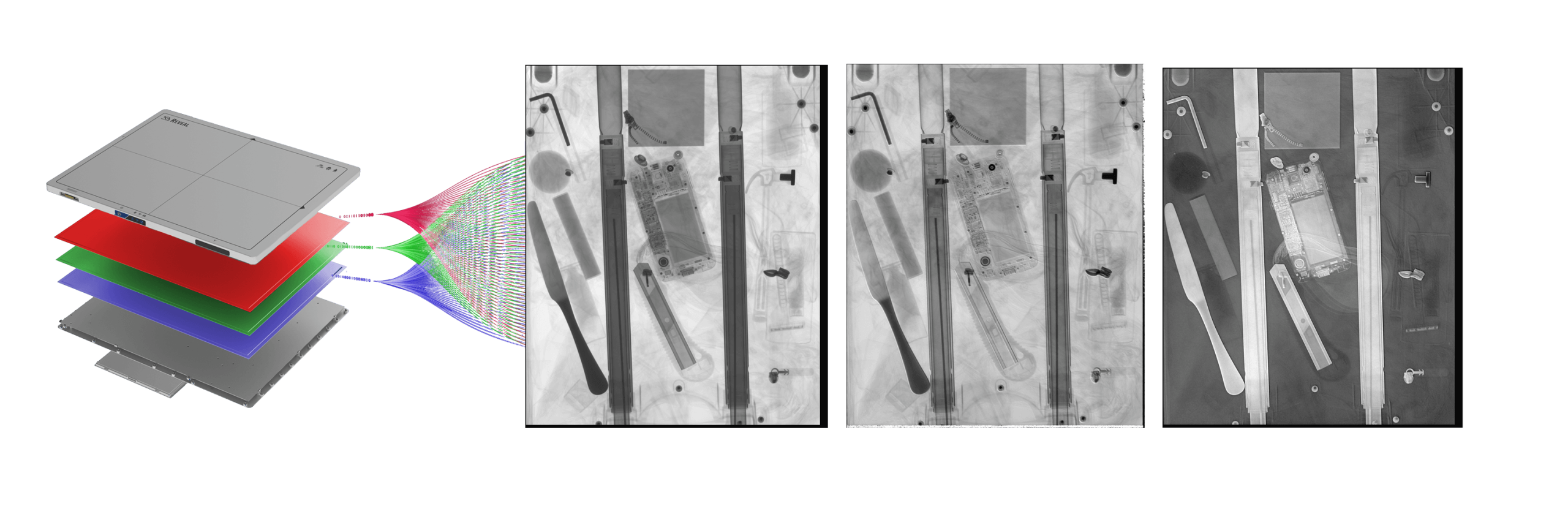

Thanks to its SpectralDR® technology, Reveal™ R 35C X-ray flat panel detector overcomes the limitations of other dual-energy X-ray technologies, enabling material identification without motion artifacts in a single X-ray exposure. In other words, with one exposure, the detector simultaneously delivers DR, high-density and low-density images, as well as a spectral color image. Its rugged enclosure offers extra protection in challenging environments.

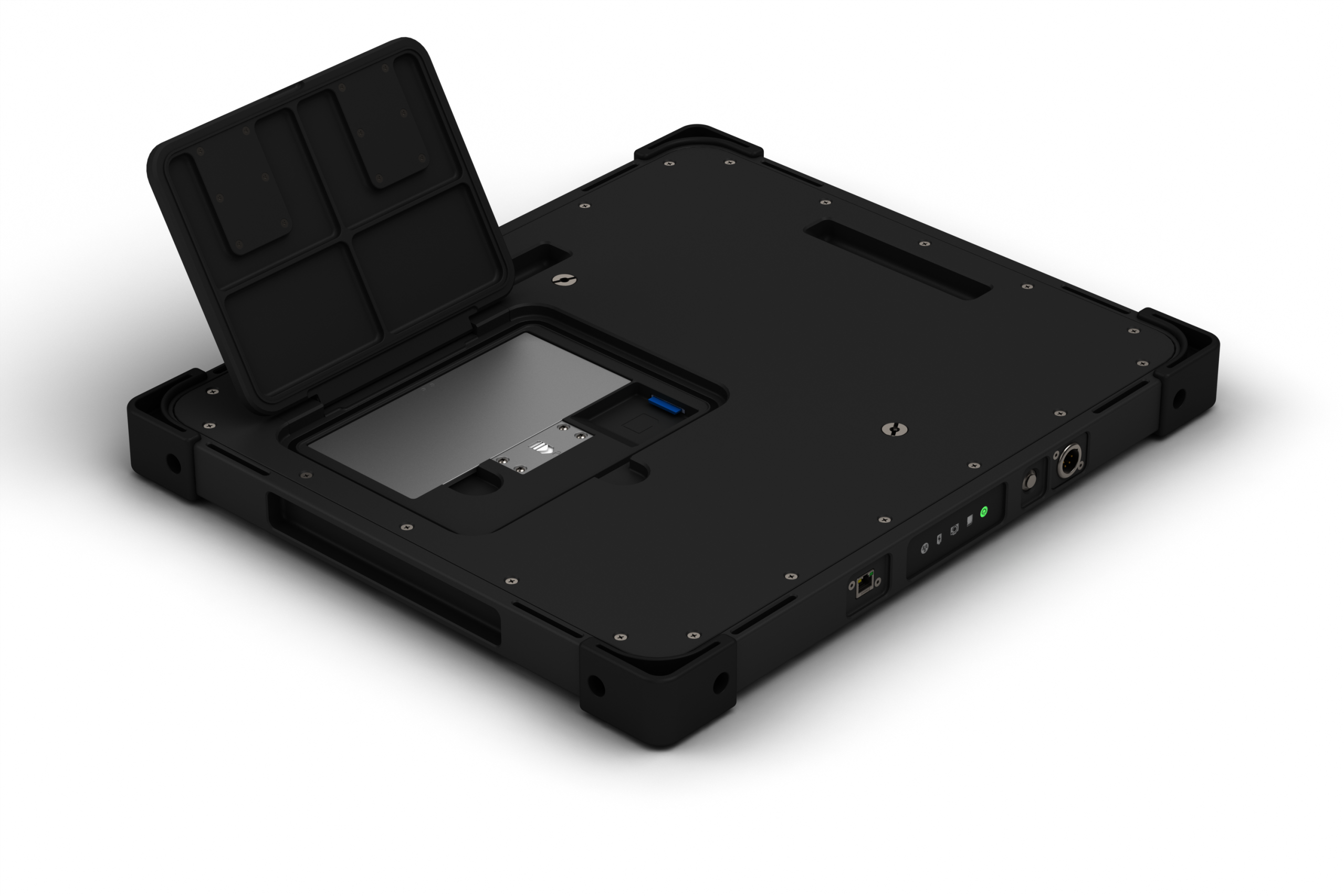

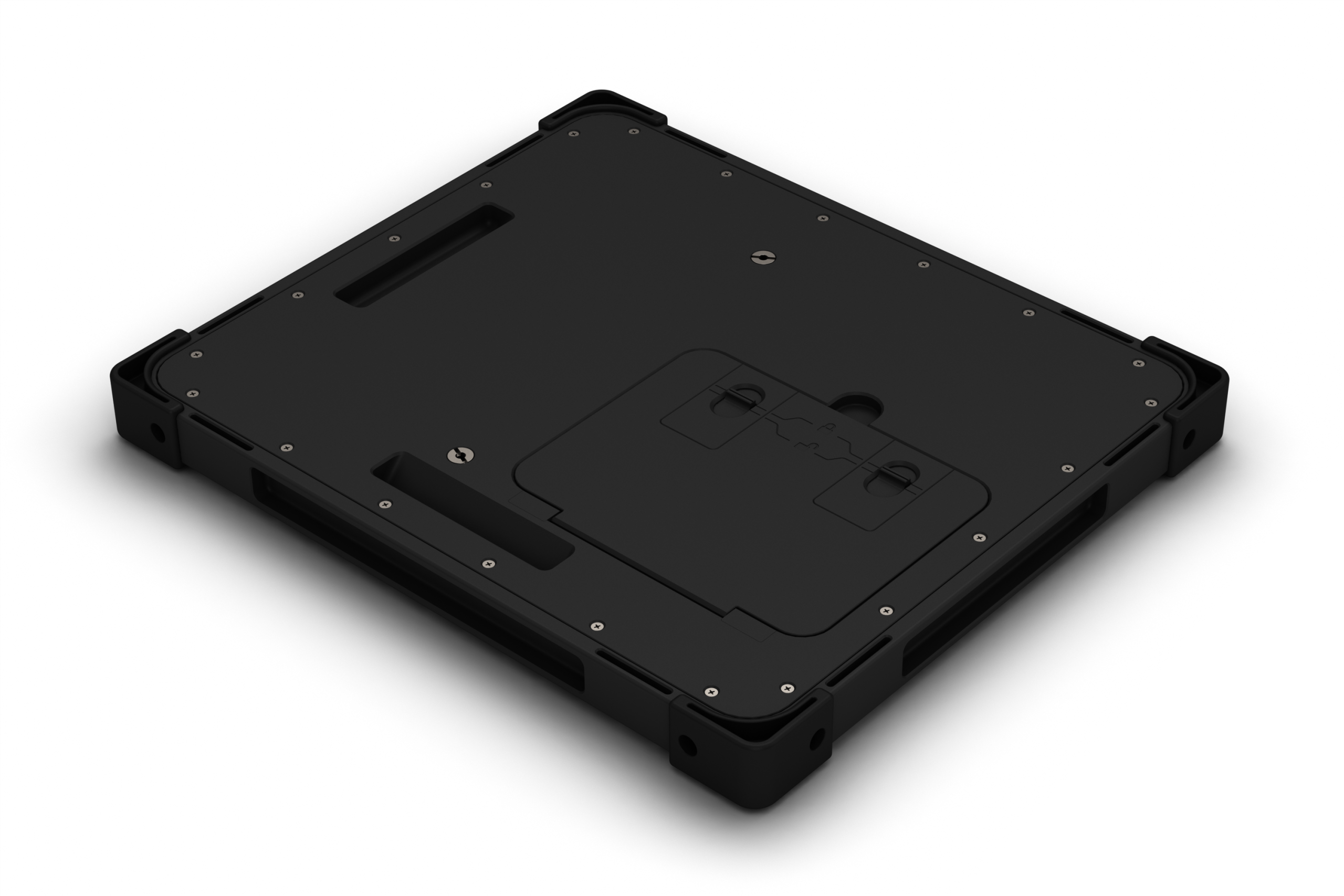

Product overview

SpectralDR® technology: 1 exposure, up to 4 images, 0 motion artifacts

Tripod quick mount bracket

Webbing strap points

Ruggedized enclosure

IP55 rating

Finger holds

Improved handling and support features

136 Kg Distributed Load 100 Kg Local Load (40 mm Diameter)

Literature

Flexible Applications

The Reveal™ R 35C X-ray Detector with SpectralDR® technology can be used in a range of fixed and mobile applications in the Non-Destructive Testing (NDT) field, including Industrial Inspection, Security, Aerospace, Electronics, and Construction. It’s fully compatible with legacy X-ray sources and techniques.

SpectralDR® technology: supplemental subtracted images for better decision-making on the move

In addition to the DR, the SpectralDR® technology in the Reveal™ 35C detector offers quick access to supplemental dual-energy high-density and low-density images. No extra radiation is needed: all images are created simultaneously with a single standard X-ray dose.

Maximize the potential of your mobile X-ray system, especially in challenging environments such as industrial sites, remote inspection locations, or applications requiring quick decisions. The extra details provided by single exposure dual-energy X-rays enhance decision-making, ensuring safety and efficiency.

Reveal™ 35C: ASTM F792-17 Compliant

The ASTM F792-17 standard, established by the Transportation Security Administration (TSA), sets guidelines for the performance and testing of X-ray screening systems used in airport security. The standard covers various aspects, including image quality, radiation safety, system performance, and testing procedures. Compliance with ASTM F792- 17 is crucial to ensure consistency and effectiveness in aviation security operations, safeguarding passengers, and air travel infrastructure against potential threats.

Testimonials

Latest blogs

EOD teams depend on the accuracy of explosive detection equipment for keeping high-risk areas like…

Explosive Ordnance Disposal (EOD) work demands precision, speed, and safety…and the tools they use must…

Micro-computed tomography (micro-CT) has been a key imaging technology for non-destructive testing (NDT), materials analysis,…